T&R Biofab said on Wednesday that its researchers published a paper describing a 3D bioprinting technology capable of printing capillaries within organoids with characteristics similar to those of human organs.

Organoids are self-organized 3D tissue cultures derived from stem cells which can replicate the complexity of an organ. However, the FDA recently announced its Modernization Act 2.0 which aims to ease mandatory animal testing before clinical trials to confirm drug safety and validity.

As a result, organoid technology, which can be effectively used in drug development by replacing animal testing, is keenly drawing interest from several companies.

However, it is crucial to create blood vessels that can supply nutrients inside the tissue when creating artificial tissue. Blood vessels can range from several millimeters (mm) in large blood vessels to tens of micrometers (μm) in small blood vessels.

Accordingly, this printing technology not only requires high precision but also a method of printing various materials simultaneously.

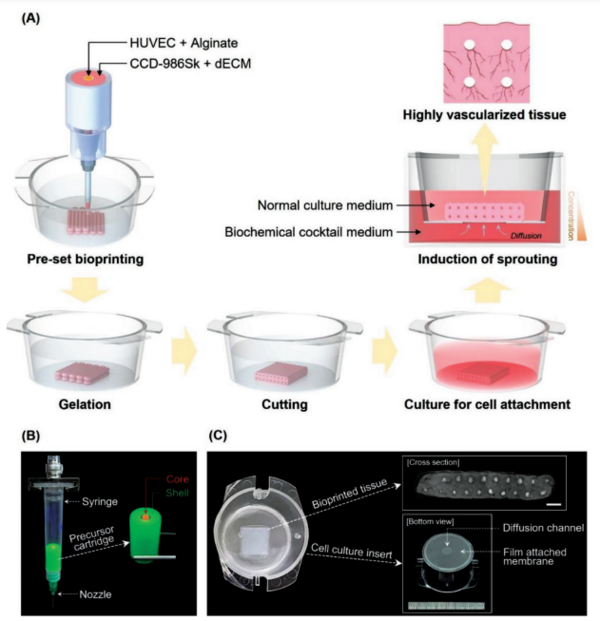

Therefore, T&R BioFab utilized a preset extrusion technology to print blood vessels of varying sizes. In particular, they used a coaxial precursor cartridge to create mid-scale vasculature embedded in tissues.

Afterward, the researchers created a biochemical gradient environment in the bio-printed tissue to replicate capillaries with vascular characteristics similar to those found in biological tissues. They demonstrated that the multi-scale vascularization technique is a promising technology for producing bioartificial organs.

"If these fabricated capillaries are embedded into the organoid it can be used as an alternative model for animal testing, to accomplish a more similar environment to actual tissues,” explained T&R Biofab Executive Director Jin Song-wan.

Jin added that the fabricated organoids can also maximize tissue survival for improved tissue survival when making tissues for transplantation to treat various diseases.

The 3D bioprinting methodology was published in the International Journal of Bioprinting on April 4.

Related articles

- New US law to replace animals in drug test likely to affect Korea

- Korea’s first ‘mini heart’ with regular heart beat created

- Next&Bio, KIST to co-develop OECD guidelines to validate organoids as alternative for animal test

- Next&Bio, CSI Singapore to co-develop cancer organoid precision medicine

- Are in silico modeling and organoids poised to replace animal testing in pharma?