MEPSGEN, a Korean firm specializing in advanced microfluidic technologies for nanomedicine development, will participate in the BIO International Convention 2024, which will take place from June 3-6 in San Diego, the U.S.

The company specializes in developing high-efficiency and high-throughput systems for the mass production of microphysiological systems (MPS), such as organ-on-chips and organoid chips, as well as various nano-drug delivery systems.

The company will be located within the Korean Pavilion, organized by the Korea Biotechnology Industry Organization and KOTRA (Korea Trade-Investment Promotion Agency).

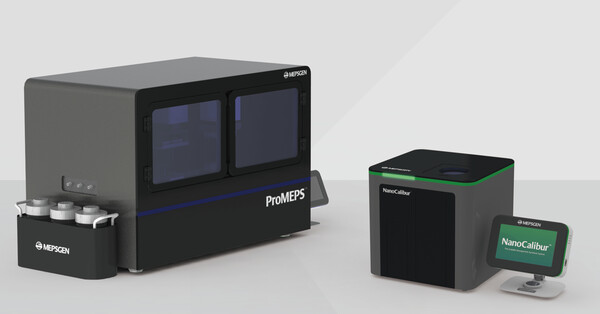

The company plans to showcase devices such as ProMEPS, an automated organ tissue culture equipment launched last November, and the upcoming NanoCalibur, a nano-particle manufacturing equipment set to be released mid-year.

ProMEPS automates the entire process of cell injection, cell culture, and perfusion formation for 3D organ tissue modeling, also providing real-time quality measurement of the developed tissues.

The device minimizes the time required for cell culture operations while ensuring the efficient and large-scale production of high-quality, reproducible organ tissue models.

NanoCalibur is an automated nano-particle manufacturing device designed to encapsulate therapeutic materials like mRNA and antisense oligonucleotides (ASO) effectively.

A bench-top research product suitable for various stages of nano-particle development, from initial particle design to preclinical animal testing, is slated for release in July. A good manufacturing practice (GMP) version for clinical and commercial manufacturing will follow in the latter half of the year.

Unlike traditional syringe pump-based nano-particle manufacturing equipment, the company stressed that NanoCalibur employs a high-precision feedback pressure control system.

This system ensures accurate flow rate control by compensating for external factors during the low flow rate control process within microfluidic chips.

"ProMEPS is expected to play a crucial role in the drug development process, particularly for biotech companies and CROs aiming to reduce reliance on animal testing,” MEPSGEN CEO Kim Yong-tae said. “Also, NanoCalibur is poised to become a key partner in the nano-pharmaceutical market, which has a high demand for nano-drug delivery systems such as mRNA."

Meanwhile, the company also plans to attend the MPS World Summit, the world's largest microphysiological systems conference, scheduled from June 10 to 14 in Seattle.

At the conference, the company plans to demonstrate ProMEPS, present three posters, and deliver an oral presentation on "3D Human Skin Tissue Modeling in a Manufactured Microphysiological System."

Related articles

- Samsung Biologics to participate in the 2024 BIO International Convention

- KoreaBIO to run largest Korean pavilion ever at BIO USA 2024

- [BIO USA 2024] Korean biotech giants take center stage at BIO USA 2024

- Mepsgen launches automated nanoparticle production equipment ‘NanoCalibur’

- Mepsgen raises $14.9 mil. in series C funding, expands global reach

- Mepsgen launches NanoCalibur GMP for automated nanoparticle manufacturing

- MEPSGEN and Korea University Professor Chung's team agree to co-develop kidney models