Mepsgen, a Korean biotechnology company specializing in microphysiological systems and nanoparticle production, announced the launch of its new bench-top automated nanoparticle production equipment, the NanoCalibur Lab, on Tuesday.

The NanoCalibur series utilizes Mepsgen's proprietary microfluidic technology to encapsulate therapeutic substances such as mRNA and antisense oligonucleotides (ASOs) into lipid nanoparticles for stable and scalable production. Developed in-house, the microfluidic synthesis chip incorporates a microvortex-inducing structure that enables high drug encapsulation rates of lipid mixtures and nucleic acid precursors, even under low shear forces.

Mepsgen said its system allows for the flexible encapsulation of both small and large molecule therapeutics into lipid-polymer nanoparticles through interchangeable microfluidic synthesis chips tailored to customer needs.

This innovation earned the company two patents in 2024: one for the chip’s structural and synthesis mechanisms and another for its method of efficiently encapsulating mRNA and ASOs. The technology builds on over 15 years of research in microfluidic engineering led by Professor Kim Yong-tae at the Georgia Institute of Technology, who also serves as CEO of Mepsgen.

Unlike conventional syringe pump-based nanoparticle manufacturing systems, Mepsgen said NanoCalibur employs a high-precision feedback pressure control system that compensates for external factors during low flow control. “This enables precise flow rate adjustments and ensures stable mass production of nanoparticles with uniform size and high drug encapsulation rates,” a company official explained.

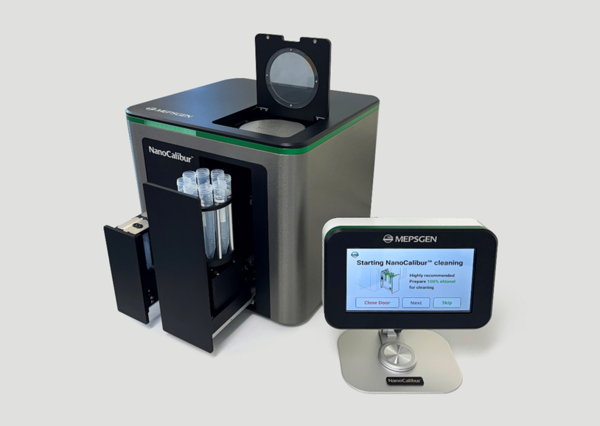

Mepsgen’s proprietary stainless-steel microfluidics-based synthesis chip, used in the NanoCalibur Lab, is designed for semi-permanent use due to an automatic cleaning feature. "This innovation enhances user convenience and cost efficiency by eliminating the need to replace the chip for each synthesis, as required by conventional systems," the company official said. adding that NanoCalibur is designed to allow users to switch between chips for producing lipid nanoparticles and lipid-polymer nanoparticles, depending on the application.

The NanoCalibur Lab is the first product in the company's NanoCalibur lineup, intended for bench-top research across various stages of nanoparticle development, from initial particle design to preclinical animal testing.

With a throughput of 3–15 mL/min, it offers rapid optimization of synthesis conditions, enabling the production of uniform nanoparticles with high drug encapsulation efficiency at the early design stage. Its production capacity of up to 1 L/hour makes it suitable for non-clinical efficacy testing as well. Equipped with a rotary multi-tube holder, the NanoCalibur Lab enhances user convenience and time efficiency by allowing multiple product variations to be synthesized in a single run.

Following the NanoCalibur Lab, Mepsgen is developing the NanoCalibur GMP, a clinical and commercial-grade version of the system, slated for release in the first half of 2025.

"The global lipid nanoparticles market is expected to grow from approximately 1.35 trillion won ($1 billion) in 2024 to about 3.81 trillion won by 2032, with an annual growth rate of around 14 percent," said Kim. "With NanoCalibur, developed using cutting-edge microfluidics technology, we aim to provide an unprecedented solution for the expanding nanomedicine market, extending beyond vaccines to cancer therapies, gene therapies, and more."

Related articles

- MEPSGEN to showcase microphysiological systems at BIO International Convention 2024

- Mepsgen raises $14.9 mil. in series C funding, expands global reach

- Mepsgen launches NanoCalibur GMP for automated nanoparticle manufacturing

- Mepsgen launches microfluidics-based nanoparticle system in US for mRNA and gene therapy

- MEPSGEN and Korea University Professor Chung's team agree to co-develop kidney models